Trench Drain Supply - 5621 Raby Road - Norfolk, VA 23502

http://www.trenchdrainsupply.com - Sales 877-903-7246 Ext 1

Trench Drain Installation Summary

These trench drain installation instructions are applicable to most installations. System designers must determine whether site conditions have special requirements regarding trench drain channel installation.

1. DRAINAGE SYSTEM DESIGNThe drainage system selected must be suitable for the customer’s application and for the location where installation is to take place.

2. PREPARATION

Read all information for your type of installation before starting

project. Collect tools and supplies needed to do the job. See list

of suggested tools and supplies in thedetailed

installation instructions.

3. EXCAVATION

Excavate trenches to a width and depth sufficient to ensure that

there is room for the minimum required thickness of concrete to be

placed under and alongside the channels. Remember that the pavement

surface next to the channels must be laid so that it is 1/8 in. (3

mm) above the top of the channel.

4. CHANNEL LAYOUT

Lay out channel system parts in the planned sequence alongside the

excavated trench according to the installation plan. Ensure that

channels are placed in the proper position and in the proper

direction. Set outlet channel first (highest channel number),

5. KNOCKOUT REMOVAL

Remove preformed knockouts from channels and catch basins for

required piping connections.

6. INSTALLATION AND BRACING

Begin installing channels at the downstream discharge end of the

drainage system. Install and brace channels so that channels will

remain in place without sagging prior to pouring concrete and so

that channels will not float out of position during or after pouring

concrete. Channels must also be braced against any side loading that

would prevent easy installation of grates after the concrete sets

up.

7. POURING CONCRETE

Do not bump or jar channels out of alignment during the pouring of

concrete. Pour concrete slowly enough to ensure that channels do not

float out of alignment and do not pour concrete directly against

channels. Pour the same amount of concrete on both sides of channels

to avoid pushing channels out of alignment. The pavement surface

next to the channels must be laid so that it is 1/8 in. (3 mm) above

the top of the channels.

8. CLEANUP

Clean any spilled concrete from grates, channels and outlet points.

Insert and secure grates to channels using the optional locking

devices.

Preparation

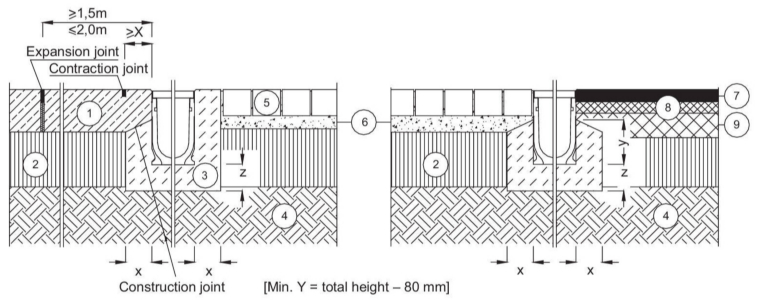

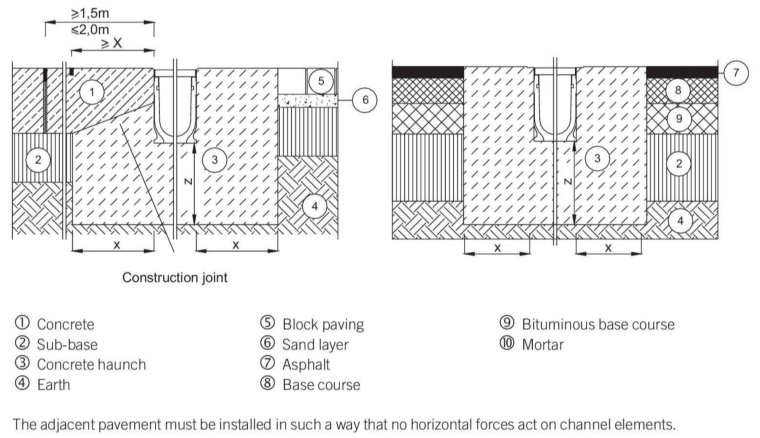

1. DRAINAGE SYSTEM DESIGN

The drainage system selected must be suitable for the customer’s

application and for the location where installation is to take

place. The carrying capacity of the subsoil and the strength of the

trench floor must be considered. Consideration should also be given

to the use of expansion joints in both longitudinal and transverse

directions to minimize horizontal forces which would distort the

channel system.

2. PREPARATION

Read all information for your type of installation before starting

project.

Collect tools and supplies needed to do the job. The following may

be useful for your installation:

| Shovel | Screwdriver | Wooden or steel stakes |

| Level | Saw with masonry or diamond blade | Grout and adhesives* |

| Square | Grinder | 2” x 4” boards |

| Chalkline | Caulk gun and caulk sealant* | Plywood |

| Large hammer | Vibrator | Gloves |

| Cold chisel | Drill and masonry bits, about 3/8 in. (10 mm) diameter |

Respirator |

| Safety glasses or goggles | 3” schedule 40 PVC pipe |

*Selection of Caulks, Grouts and Sealants:

Adhesives, caulking compounds, grouting and sealants used on the

drainage system must be compatible with all chemicals that will flow

through the system. Openings and joints may be filled with one of

several materials. Silicone caulk should be used when a flexible

joint is needed. A two-component epoxy grout should be used when a

rigid joint is needed. A fast setting cement type grouting compound

may be used where high durability is not needed.

EXCAVATION

Example Installations:

Load Class A

Load Class B

NEXT: Channel Layout

CHANNEL LAYOUT

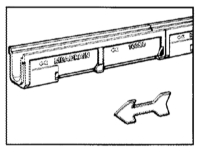

4. CHANNEL LAYOUT

Lay out channel system parts in the planned

sequence alongside the excavated trench according

to the installation plan. Ensure that channels are

placed in the proper position and in the proper

direction. The number on the side of each channel

shows the position of the channel within the drainage

line. The direction of flow is shown by arrows on the

channel sides which point to the outlet.

5. KNOCKOUT REMOVAL

Drill holes around the perimeter of knockout breaking

point using a masonry bit about 3/8 in. (10 mm)

diameter. Carefully remove the knockout from inside

the channel using a hammer and cold chisel. Clean

up edges of hole using a hammer and cold chisel or a

grinder. Invert channel and insert outlet connector

from bottom and apply sealant. Allow proper time for

sealant to set before handling. Catch basins and outlet channels contain preformed

cutouts for piping, channel and catch basin conn. Remove these knockouts only as needed.

CAUTION Knockouts should be removed carefully in order to prevent cracking of the channel around the knockout hole.

WARNING

Wear protective eyeglasses or goggles, a respirator mask and gloves

when cutting, chiseling, drilling or grinding concrete or asphalt.

Avoid breathing concrete and asphalt particles since they could be

harmful to your health. Observe all safety precautions

when operating electrical or hand

tools.

NEXT : Installation and Bracing